charpy impact test numbers|charpy impact test explained : services The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized . Resultado da Nossos doces gourmet são ou não são um charme além de deliciosos? Turfinha de limão Photo by: @wiltonburregofotografo #casinha .

{plog:ftitle_list}

Resultado da O Nerdcast completou 10 anos em 2016 com 1 milhão de downloads por episódio e como primeiro lugar de audiência em podcasts no Brasil. Os assuntos são história, ciência, cinema, quadrinhos, literatura, tecnologia, games, RPG. Tudo que um nerd gosta! A conversa é informal, divertida, .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .Over 250 pipeline-specific calculations to solve everyday pipeline integrity, construction, operations, and design challenges. A Charpy impact on pipelines test evaluates the response of a notched steel specimen to impact loading to .

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface.The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

We also provide two SRMs that are used to verify the measurement of maximum force in a Charpy impact test, and SRMs for the verification of small-scale impact machines (miniaturized Charpy specimens). . The total . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .Test results, especially in Europe, may be reported as energy lost per unit cross-sectional area (J/m 2 or ft-lb/in 2). What are the test methods to measure toughness? Test methods used to measure Notched Izod Impact (or notch .

Explore the Charpy V-notch impact test, a standard measure of a material's impact energy during fracture. Understand the variables affecting test results, its applications in industries, and the standard procedures as per British and American standards. . Impact testing is important for a number of applications but some key examples are in . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type (b)To determine the variation of impact strength of a material with change in temperature . The impact testing machine calculates the energy absorbed, which can be . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force sensors on the striker's edge, allowing scientists to record the .

is a compression test needed to check blown gasket

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.ASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum.

Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. . Additional Phone Numbers. APAC +65 6805 4800. UK - Wilton +44 1642 435 788. Benelux +31 88 126 8888 .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy . the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . as a way to verify the numbers .

is a root bend test a toritonal compression or tension

Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. . A higher number indicates a tougher material. Charpy Impact ISO 179 ISO .An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a . During WW2, a large number of failures occurred in Liberty ships (cargo ships) – over 20 % fractured from February 1942 to . Additional information can be obtained from a Charpy impact test if the machine striker is instrumented with strain gages (instrumented The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. . Impact Testing – Charpy and Izod Tests. The impact testing .

The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height h i, . A number of studies failed to report significant details including loading span [35–37,45–49], aggregate size [46,48], and fiberTo determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated .In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurements of absorbed energy and lateral expansion are quantitative and well defined, but the methods used by most laboratories in the measurement of percent shear are qualitative at best.

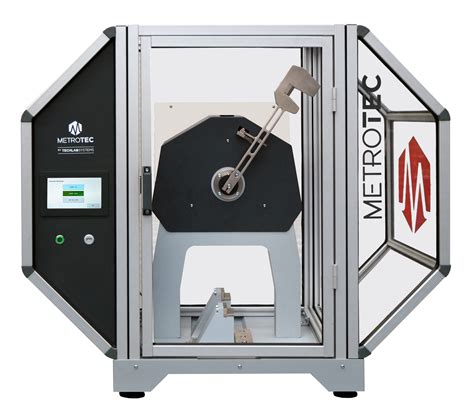

charpy impact tester

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . Impact energies for a number of engineering materials are entered in Table 7-5 where they may be compared with .

Alternatively call us on the number below for professional, no obligation advice +44 01522 401375 [email protected] Request a quote. Name* * Email* * Phone . Charpy Impact Test. The most common test methods for this test are. ISO 148 ASTM E23, ASTM A370, EN 10045-1. For polymers the methods are ISO 179 & ASTM D6110specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2.ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test parameters are specified according to the type of material, the type of test specimen and the type of notch. Compatible with the full range of CEAST impact testing systems, including pendulum type machines (CEAST 9000 Series) and drop towers (CEAST 9300 Series), it’s the key for instrumented impact testing. The DAS 64K also enables the data collection from instrumented tups or hammers on older models and non-CEAST impact machines. Products .

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.Charpy impact test ISO 179 and ASTM is for determining toughness, or the tendency of a material to resist breaking on being subjected to sudden shock. A 3 point bending test configuration, where a notched specimen is supported on both ends and an impact hammer strikes the middle to break the piece in half.

charpy impact test sample dimensions

is code for compression test

web4 de jan. de 2024 · Phone number 8008882238 has negative rating.79 users rated it as negative and 7 users as positive.This phone number is mostly categorized as Debt collector (44 times), Nuisance call (10 times) and Telemarketer (7 times).This ratings are based on reports of visitors of this web site and reports from users of our protection agains .

charpy impact test numbers|charpy impact test explained